Horizontal Drilling Technology

Ranger - The Future of General Contracting

Horizontal Directional Drilling

At Ranger Construction Corporation, we strive to provide the very latest technology in our quest to deliver the best, fastest, most efficient and least disruptive means of handling your new or restorative municipal water and sewage installations.

As you will see from this industry video, a combination of horizontal boring equipment and radio-frequency controls allows us to make a safe passage for your lines with minimal destruction of road surface with the best potential for a quick resolution to your emergency, scheduled maintenance or upgrade requirements.

To learn more about how Ranger can bring these New Technologies to your project: Schedule a call with one of our Site Specialists.

An Overview

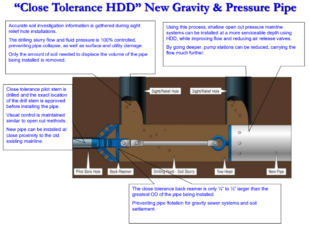

Ranger, Inc, a division of Ranger Construction Corp is a regional leader in new methods and technologies like CTHDD (Close Tolerance HDD), a modification of standard HDD process where vertical sight holes are drilled about every 15 to 50 feet over the alignment to facilitate sighting the pilot bore and to relieve the drilling mud pressure. As the product pipe is pulled into the reamed hole, the drilling mud is displaced up the sight holes and is vactored out of the holes.

As the product pipe passes the first sight hole, the path of the drilling mud is effectively shifted to the next sight hole. A sample situation would be when three water lines must be installed as temporary pipelines for bypass flow to allow CIPP lining of the larger diameter water transmission lines. The design engineer specified HDD for installation of the three temporary water pipelines. During the submittal review phase, the contractor proposed using the CTHDD technology.

Ranger Construction Corporation Vision Statement:

Ranger Construction Corp., a Central Maine based excavation and civil construction firm, was born from a focused “vision” of serving the community by creating jobs while providing experienced, quality, and safe construction services. Several years later, Ranger has grown to be one of Maine’s most capable and reputable civil construction firms.

Ranger Construction Corp Office:

Ranger Construction Corp is a Registered Veteran-Owned Small Business